KEJE THERMOWELD EQUIPMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KEJE THERMOWELD EQUIPMENTS P.LTD.

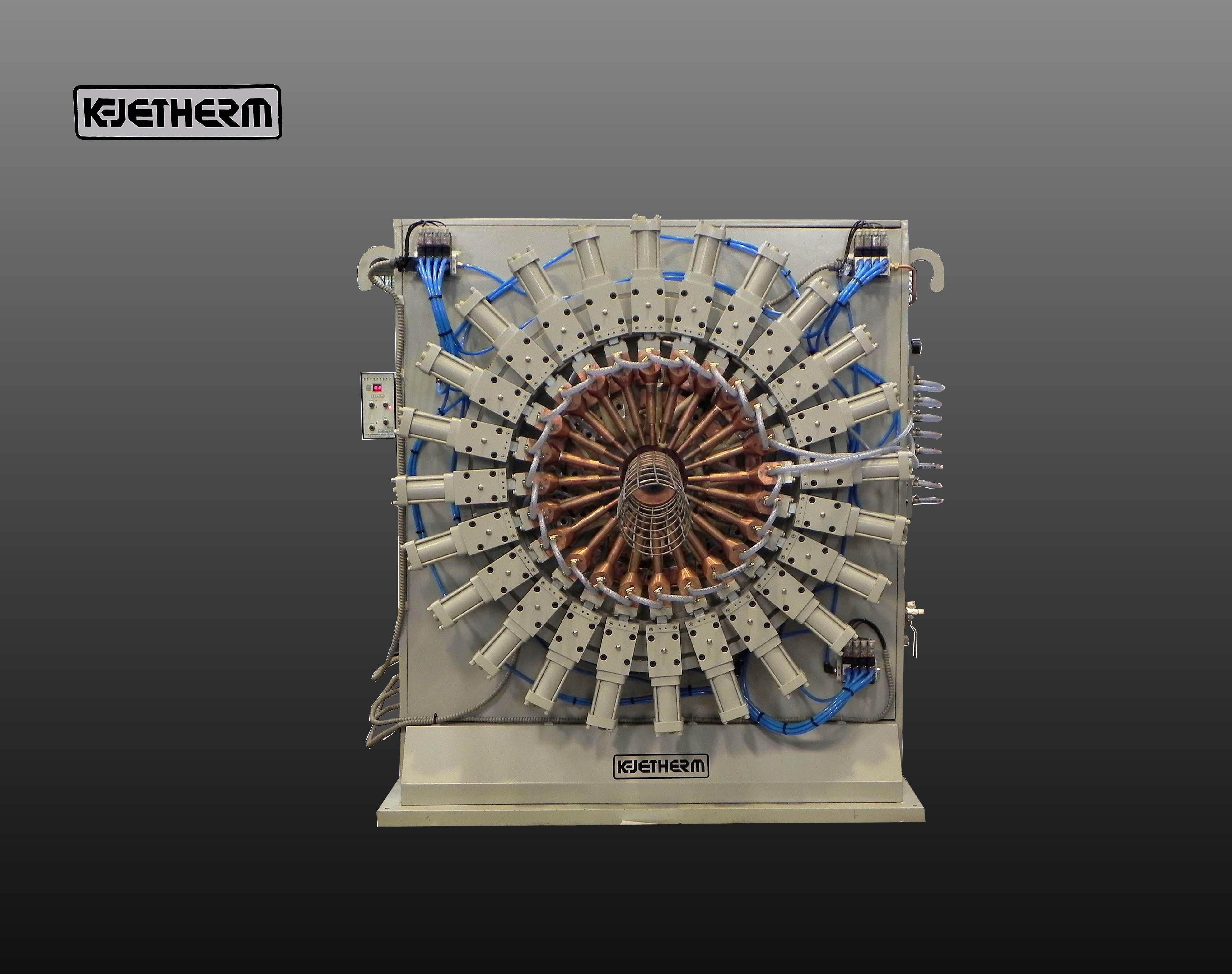

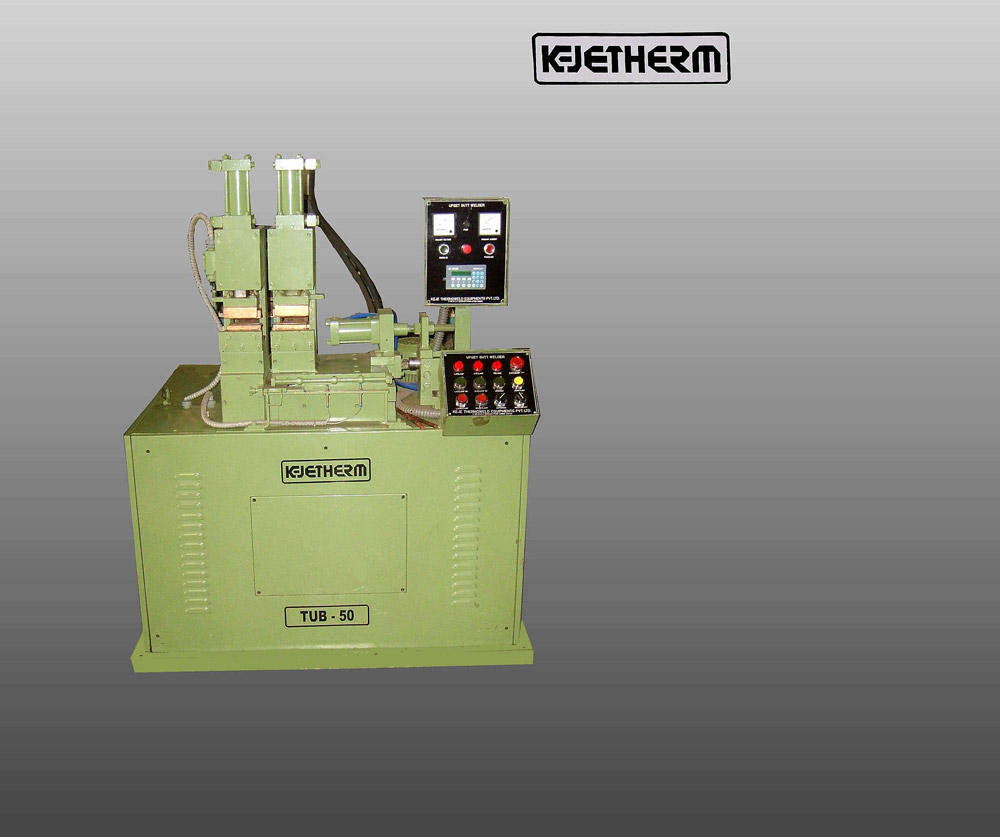

Hydraulic Flash Butt Welder Machine

INTRODUCTION

Flash Butt Welding is a modern technique of joining mild steel, alloy steel and other dissimilar metals in various tubular or solid sections. Weld quality obtained is mechanically or metallurgically similar to the parent metal. Because of shorter weld times the process is suited for higher production than other conventional methods. No additional items such as rods or gas etc. are required thus it is highly economical. Other features include (a) little or no end preparation (b) High accuracy of welding joints (c) High consistency of weld parameters.

Applications

Welding of HSS to EN9 tools, tubular parts, bicycle and moped wheel rims, starter ring gears, window sections, table knives, construction steel bars upto 30 dia., bottom rings of cylinders, continuous coil strips.

Salient Features

- Fully Hydraulically operated.

- Forced Air Cooled transformer having core of high grade silicon steel confirms to IS 4804, Part II.

- Precision control on initial die opening. Flash off length, Time, length and final die opening.

- Precision time delay circuit for upset current.

- Safety and sequential interlinks provided for prolonged trouble free Tooling operation.

- Pre-heat and Post heat cycles available as required.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.